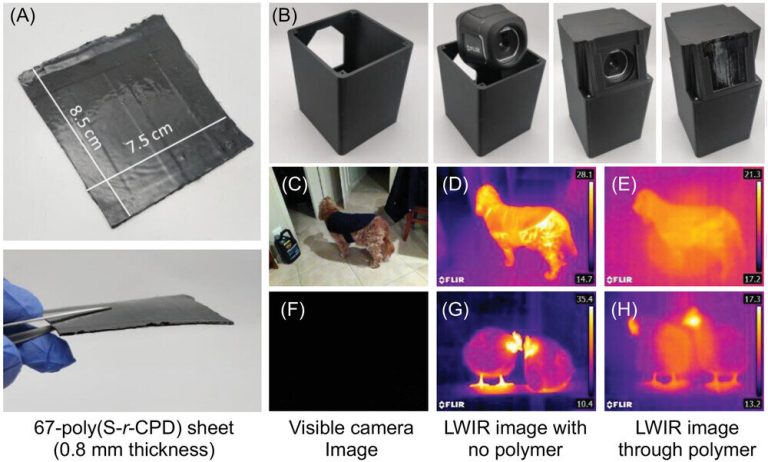

A) Top and side views of a 0.8 mm thick 67-poly(Sr-CPD) polymer sheet. b) 3D printed protective housing for FLIR camera. 67 Poly(Sr-CPD) polymer sheet was used to mask and protect the front of the FLIR camera. C) Visual image of dogs taken with a FLIR E6 camera in home lighting. D) LWIR image of dogs taken without a polymer sheet. E) Long-wave infrared image of dogs taken through 0.8 mm thick 67-poly(Sr-CPD) polymer sheets in household lighting. f) Visual image of chickens taken in low light at night. G) LWIR image of a chicken taken in low light at night without a polymer sheet. h) Long-wave infrared image of a chicken taken through 0.8 mm thick 67-poly(Sr-CPD) polymer sheets in low light at night. All LWIR images were captured with a FLIR E6 thermal camera over the wavelength range of 7.5–13 μm. credit: Advanced optical materials (2023). doi: 10.1002/adom.202300058

× Close

A) Top and side views of a 0.8 mm thick 67-poly(Sr-CPD) polymer sheet. b) 3D printed protective housing for FLIR camera. 67 Poly(Sr-CPD) polymer sheet was used to mask and protect the front of the FLIR camera. C) Visual image of dogs taken with a FLIR E6 camera in home lighting. D) LWIR image of dogs taken without a polymer sheet. E) Long-wave infrared image of dogs taken through 0.8 mm thick 67-poly(Sr-CPD) polymer sheets in household lighting. f) Visual image of chickens taken in low light at night. G) LWIR image of a chicken taken in low light at night without a polymer sheet. h) Long-wave infrared image of a chicken taken through 0.8 mm thick 67-poly(Sr-CPD) polymer sheets in low light at night. All LWIR images were captured using a FLIR E6 thermal camera over the wavelength range of 7.5–13 μm. credit: Advanced optical materials (2023). doi: 10.1002/adom.202300058

Researchers at Flinders University have discovered a new low-cost material that can be turned into lenses for thermal imaging, suggesting new advanced manufacturing applications for this powerful technology.

Thermal and infrared imaging are used in many industries, including defence, security, surveillance, medicine, electrical engineering, space exploration and the operation of autonomous vehicles, but the materials required are expensive and becoming more difficult to find.

Less expensive alternatives are needed, so an interdisciplinary team in chemistry and physics at Flinders University has developed a solution in an entirely new polymer material made from sulfur and cyclopentadiene. They say the high-performance polymers have a unique ability to transmit infrared light.

“The material combines high performance, low cost and efficient manufacturing,” says Ph.D. Candidate Sam Tonkin, first author on a new article in Advanced optical materials magazine.

“It has the potential to expand the use of thermal imaging to new industries that were previously limited by the high cost of germanium or chalcogenide lenses,” he says. “This is a rapidly developing field that will see exciting developments in the next few years.”

Sulfur is produced in millions of tons in oil refining. Billions of tons are available in geological deposits. It is abundant and cheap.

Cyclopentadiene is also derived from low-cost materials produced in petroleum refining.

Lenses used for thermal imaging are currently made of germanium or chalcogenide glass. Germanium is an element in short supply and is very expensive. Some germanium lenses can cost thousands of dollars.

Chalcogenide glasses also have disadvantages. For example, they are often made of toxic elements such as arsenic or selenium.

Together, the reaction of sulfur and cyclopentadiene provides a black plastic with high transparency to infrared light, says co-author Dr Le Nhan Pham, a computational and physical chemistry researcher at Flinders University.

“This is the light that thermal imaging cameras detect.

“This new material is designed to have a wide range of potential applications from aerospace engineering to military operations and the civil and aerospace industries,” he says.

The polymer can be formed into a variety of lenses, which can be used, for example, to enlarge the image in a thermal camera. Because the polymer is black, it can also be used to mask and protect thermal imaging equipment. Thus the polymer can be used as camouflage to hide the camera used for surveillance.

Infrared light passes through the polymer, so one can see through it using an infrared camera. This feature is useful for defense operations and wildlife monitoring.

The polymer also has many other features:

- The material has the highest transparency in long-wave infrared light ever seen for a plastic.

- Low-cost raw materials: For a 1 gram lens, the basic components cost less than 1 cent.

- The material allows rapid molding into different shapes such as lenses. This is a faster process than current lens production, which relies on slow grinding methods.

The study also reported on some key scientific developments, including a new reactor designed to enable the key reaction. The main challenge was the ability to use the building blocks in gaseous form. The use of gaseous monomers was previously thought not possible by other researchers in the area.

The study also includes quantum mechanical calculations to understand how and why the material is transparent to infrared light used in thermal imaging. These insights will also be useful in the future for designing new lenses with more improved properties.

more information:

Samuel J. Tonkin et al., Thermal imaging and covert surveillance using low-cost polymers with long-wave infrared transparency, Advanced optical materials (2023). doi: 10.1002/adom.202300058

Magazine information:

Advanced optical materials