In conversation with Vikrant Rawa, Chief Technology Evangelist at Intriguity, a company providing high-tech solutions to the jewelery industry, Solitaire delves into the dynamic landscape of technological breakthroughs reshaping the Indian jewelery manufacturing industry. Roy provides insights into the strides made over the past five years and forecasts the trends that will define this sector in the near future.

What are the most important technological breakthroughs in the jewelry industry that have occurred in the past five years? This is done across areas such as CAD/CAM, advanced materials, new alloys, gem cutting and setting, 3D printing, automation, blockchain, artificial intelligence as well as any others.

The jewelery manufacturing business in India has witnessed rapid growth over the past decade and this has led to many innovations and changes in jewelery manufacturing processes. One of the major drivers of technological change is the demand for new designs by end customers which has led to increased adoption of CAD/CAM technologies.

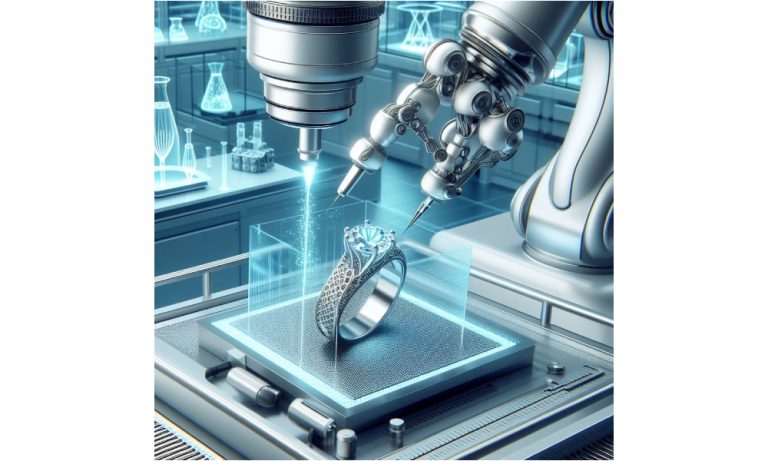

Traditional mold-based processes that were used to produce hundreds of similar designs had to be replaced by direct manufacturing processes where each design was printed and then cast directly in a limited quantity. This has led to the adoption of direct castable wax and resin 3D printers that have the ability to adapt to ever-changing designs.

Organic shapes, which can be created with new software tools such as Zbrush, inspire new designs that challenge traditional manufacturing methods. To produce these complex shapes, processes such as electropolishing are becoming more popular, as they can handle complex shapes that manual finishing methods cannot.

On the other hand, gold prices are driving demand for ultra-lightweight jewelry that can only be produced by CAD/CAM and advanced casting machines capable of casting very thin sections. It is very difficult to finish these files using manual methods, which paves the way for greater adoption of automation in finishing techniques.

We are also seeing greater automation in jewelry processes that previously had almost no automation such as stone setting. Robotic systems capable of setting stones on a large scale are now available on jewelry of certain design styles.

Advanced CNC systems are pushing the boundaries of technology in many jewelry categories such as CNC cut bracelets, die stamped jewelry, and many other such sectors. We are also seeing the emergence of additive manufacturing systems that have the ability to print gold directly using SLS (selective laser sintering)-based 3D printing.

Newer alloys now offer more options to the buyer in terms of color and karat, and the 10 and 14 karat gold jewelry market is just getting started. On the marketing front, jewelers now seem to be more confident in investing in e-commerce channels to boost sales. A whole gamut of new technologies have emerged in enhancing the jeweler's online capability which includes automated photography, augmented reality (AR), visual effects, virtual showrooms, RFID, e-commerce in the marketplace, etc.

Overall, the technological improvements the jewelry industry has seen in the past five years are unprecedented, paving the way for improved designs, finishing, and productivity.

What trends/developments do you anticipate in jewelry manufacturing technology over the next five years, and how might these developments impact the industry?

The next five years will see greater adoption of CAD/CAM systems, automation systems in various aspects of jewelry manufacturing such as casting, stone setting, etc., and automated finishing systems such as electropolishing. There can also be adoption of direct manufacturing systems using additive manufacturing with the ability to produce gold patterns directly. The demand for lightweight gold jewelry will increase if gold prices continue to rise, and this means manufacturing processes for making lightweight jewelry.

Making lightweight jewelry using electroforming methods will continue to grow as will the use of CAD/CAM and manufacturing methods for wire mesh jewelry. The trend towards 10k, 14k and modern jewelery will bring the latest alloys and metal compositions to the forefront and manufacturing processes to produce unique metals like titanium, steel etc will have a greater role.

What new technology/processes can manufacturers incorporate to reduce gold waste and costs, speed up stud jewelry production, and improve quality?

To get started with CAD/CAM, this is extremely important for every jeweler who creates cast jewelry. This will significantly reduce time, reduce cost and improve quality. Professional casting systems and materials also improve quality, reducing the need for heavy polishing methods and if combined with a good electropolishing system, can significantly reduce waste, labor and costs. Automation in stone setting is still in its infancy now, however, once fully adopted, it could lead to significant cost reductions and time savings.

Are we in danger of losing traditional jewelery making skills to modern technology, or will the two coexist?

Traditional jewelery making has its own place especially in India. Although more and more automation is emerging in cast and machine-made jewellery, the traditional craftsmanship is still present in hand-crafted gold jewellery, and this market is still very active in India. This type of craftsmanship is also seen in Kundan jewelery and constitutes a very large market especially the bridal sector.

Traditional handicrafts are unlikely to decline, as there is still demand for handcrafted jewelery in India. However, finding skilled labor for these sectors is a challenge. These groups have not witnessed significant technological progress, as they rely on manual labor. Therefore, the traditional handcrafted jewelry and jewelery industry will coexist with modern technology for the foreseeable future.

Is the Indian jewelery industry developing its own indigenous technology incorporating traditional elements and techniques?

There is no doubt that indigenous technology has always been present in the Indian jewelery industry as many machines have been developed and manufactured in India many decades ago. These machines include chain making, casting, ball cutting, die making and stamping, etc. India has always been a jewelery machinery hub and even an exporter in several sectors.

However, recently, innovation is also happening in some advanced technology areas such as 3D printing, electropolishing, CNC machines, etc., where previously only European companies were present. This is very encouraging and coincides with India's technological growth.

Many companies providing IT solutions around jewelry manufacturing also play a major role in the global jewelry market. India has always been a major player in the global jewelery market, and with these technological advancements, we are all set to continue dominating this market.